As its name implies, the mobile crusher is a kind of new mobile crushing plant, which combines many equipment together by vehicular way. Mobile crushers are widely used for crushing mineral ores or stones, recycling construction wastes, producing aggregate and building highway or railway, etc. Thus we can say the mobile crusher plant enjoys the features of great mobility and wide application range.

The mobile crusher has four types: cone mobile crushing plant, jaw mobile stone crusher plant, impact mobile crushing station and mobile vertical impact crusher.

We install the hydraulic cone crusher in cone mobile crushing plant. Thus the cone mobile crusher can operate automatically. Compared with other mobile crushers, the cone mobile crushing plant can work more easily and flexibly.

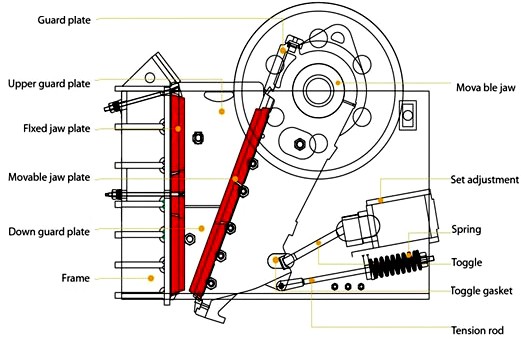

The jaw mobile crushing station is equipped with PE series jaw crusher. Jaw mobile rock crusher can fully adapt to the diverse situations like working site and environment, etc. Users can flexibly make disposition forms according to the type of raw material, production scale and requirements for finished products.

All parts of impact mobile concrete crusher plant are loaded by vehicular way. Since the impact mobile stone crusher plant has remarkable features of big crushing ratio and perfect shape of finished products, many industries would like to take this machine into actual utilization.

The vertical impact mobile crusher plant is equipped with VSI crusher, vehicular feeder and vibrating screen, etc. Either for the coarse, secondary or tertiary crushing, the vertical impact mobile crusher can still work flexibly and efficiently.

.jpg)