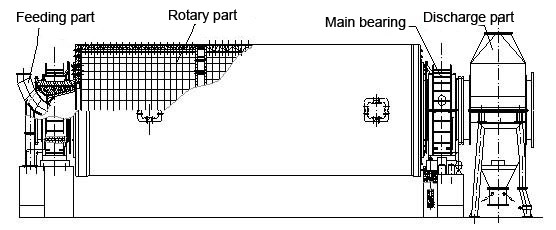

General silica sand processes are: A, wet grinding; B, multi-stage crushing and screening plant composed of impact crusher or jaw crusher. However, the above two processes have defects in some aspects. On this basis, we develop a new technical process, which includes the jaw silica sand crusher and impact silica sand crusher machine, etc.

Email: sales603@sinoftm.com

Advantages of new quartz sand crusher

1. As to the equipment investment, the new process saves almost 50% than the above two processes.

2. With regard to the process way, the new process adopts dry crushing and grinding, which is more convenient and economical compared to wet grinding.

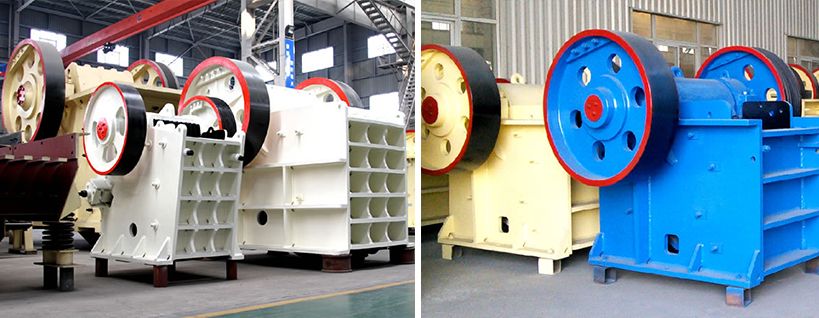

Silica sand crushers

1. Compared with the ordinary jaw crusher, the jaw silica sand crusher has higher crushing capacity and less energy consumption. If you want a silica sand crusher for coarse crushing, the jaw silica sand crusher is good choice for you. As we all know, problems of wear and plug are negative to prolong the service life of quartz sand crusher. However, the jaw silica sand crusher machine equips advanced jaw plate and no-blind cavity, you can use it for a much longer period than the ordinary jaw crusher.

2. With regard to the secondary crushing, you can use the impact silica sand crusher machine. It tops first among all quartz sand crushers in the world. With remarking features of high crushing efficiency and strong resistance to wear, the impact silica sand crusher machine must be a good helper for you.

.jpg)